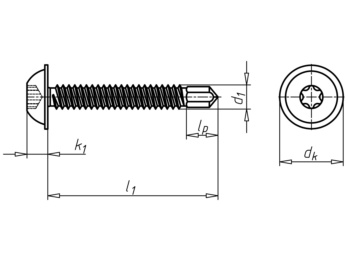

pias® drilling screw, round head with collar and AW drive

pias steel zinc plated pan head AW with flange

SCR-DBIT-PANHD-FLG-AW20-(A3K)-4,2X13

Art.-no. 021814213

EAN 4046778454757

Register now and access more than 125,000 products

Drilling, threading, screwing-in - all in one work step

Therefore considerably reduced time and effort

Exact drilling diameter for each screw connection

- Resulting in minimisation of thread tolerance

- Always an optimum connection

Prevents installation errors

AW drive system:

- Enhanced torque transmission

- Longer service life

- Optimum centring

- Better mounting output thanks to fatigue-free screwing in; the required contact pressure for transmission of the torques is considerably lower

- Largest possible contact surface of bit in screw drive

- Even force distribution prevents damage to the surface-protection coating and therefore ensures better resistance to corrosion

- The pressed-on flange generates a lower surface pressure, which helps to prevent stress cracks

- Contact pressure during use approx. 100 N/screw in with depth stop if necessary

- Drilling screws must be processed with a suitable drill driver (e.g. cordless drill driver with depth stop)

- The use of impact screwdrivers is not permitted

- Drilling screws must be attached perpendicular to the surface of the component

Galvanized drilling screws may only be used where dampness is not to be expected.

For fasteners with a construction approval, the approval, and in particular Part 2 "Special regulations", must always be observed.

Datasheets(X)

CAD data (available after login)

The self-drilling screw for fastening plastic and thin sheet metal to metal sub-structures.

| |

Material | Steel |

Surface | Zinc plated |

Nominal diameter (d1) | 4.2 mm |

Length (l1) | 13 mm |

Head diameter (dk) | 11.0 mm |

Head height (k1) | 2.9 mm |

Drill tip length (lp) | 3.7 mm |

Other standard | Company standard |

Head type | Pan head with collar |

Internal drive | AW20 |

Thread type | Self-tapping screw thread |

Thread design | Full thread |

Min. recommended substructure thickness | 1.5 mm |

Max. material thickness to be drilled through (metal) | 3.5 mm |

Max. attachment thickness (lB) | 6 mm |

Min./max. recommended installation speed (idling) | 1700-2500 rpm |

RoHS-compliant | Yes |