W-UR F 10 SymCon plastic frame fixing with zinc plated steel hexagon head bolt, flat collar and SymCon thread

Plastic frame anchor W-UR F 10 SymCon hexagon head

ANC-(W-URF SYM)-PLA-AW40-(A2K)-10-10X50

Art.-no. 5911010201

EAN 4052712325083

Register now and access more than 125,000 products

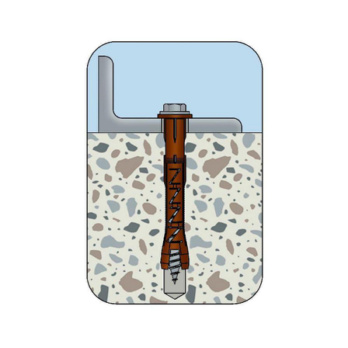

Secure anchoring

- Concrete specialist due to general type approval for individual fixing point in concrete

- Reliable follow-up expansion capability due to ingenious anchor geometry

- The teeth expand in four directions and claw into the base material

- Anchorage via friction locking between anchor sleeve and base material

- High loads due to expansion in four directions

- Improved load transmission through even, continuous load transfer across the entire expansion area

- Virtually no spinning of the anchor sleeve due to low installation torque and expansion

- Anchor sleeve made of high-quality polyamide

- Very strong anti-rotation lock

- Does not require an additional U-washer and prevents contact corrosion

Effortless installation process

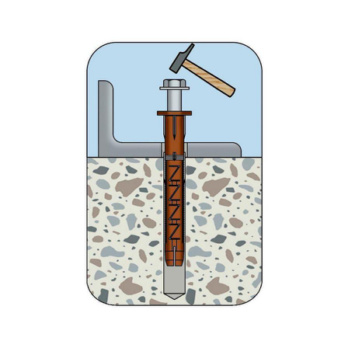

- Time savings due to immediate load-bearing capacity

- Minimal installation work because the anchor sleeve and special screw are pre-assembled

- Hammer-in stop prevents premature expansion of the anchor during installation

Multiple embedment depths

- Masonry: Two embedment depths (50 and 70 mm)

- Concrete: Three embedment depths (40, 50 and 70 mm)

European Technical Approval ETA-11/0309

When anchoring in solid brick and solid sand-lime block, we recommend performing pull-out tests due to differences in brick manufacturing

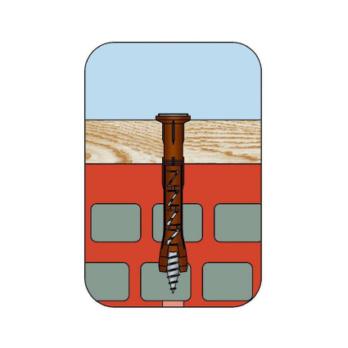

Metal substructures

Metal substructures

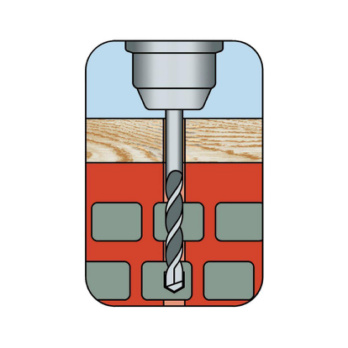

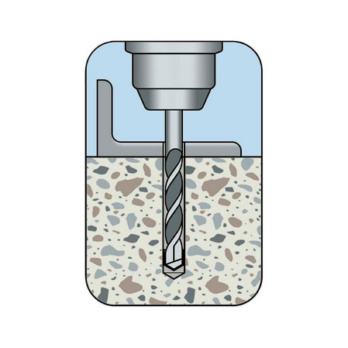

Create the drill hole

Create the drill hole

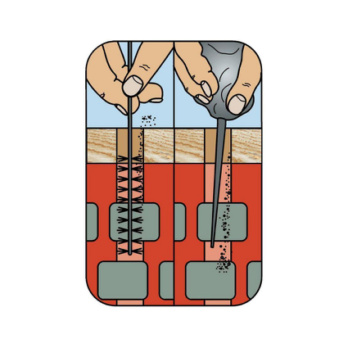

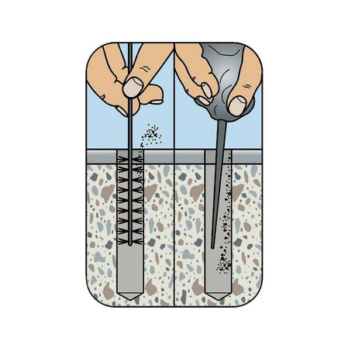

Clean the drill hole

Clean the drill hole

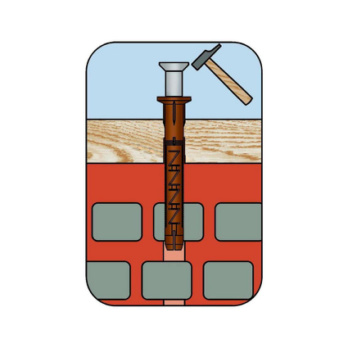

Set anchor and screw

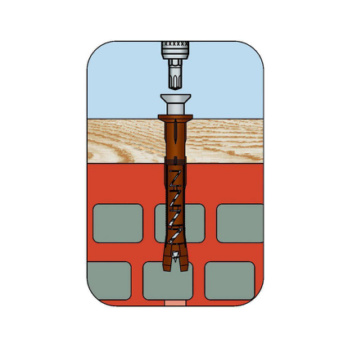

Screw in the screw

Screw in screw until flush

Create the drill hole

Create the drill hole

Clean the drill hole

Clean the drill hole

Set anchor and screw

Set anchor and screw

Screw in the screw

Screw in the screw

Screw in screw until flush

Screw in screw until flush

European Technical Approval ETA-11/0309

Datasheets(X)

CAD data (available after login)

- Suitable for fastening façades, suspended ceilings, roof substructures made of wood or steel, wooden beams, wooden laths, angle brackets, wall-mounted cabinets, shelves etc.

- Suitable for anchoring in normal weight concrete masonry walls such as solid brick, solid sand-lime blocks, vertically perforated brick, hollow sand-lime blocks, hollow lightweight concrete blocks, solid lightweight concrete blocks, concrete bricks

- Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

- Drill cuttings must be removed from the drill hole

- Installation temperature in base material ≥ -20 °C

- Installation temperature of the anchor sleeve ≥ 0 °C

Anchor diameter | 10 mm |

Anchor length (l) | 50 mm |

Nominal drill-bit diameter (d 0) | 10 mm |

Through-hole in the component to be connected (d f) | 10.5 mm |

Attachment height (t fix 1) | 10 mm |

Material of screw | Steel |

Internal drive | AW40 |

Surface of the screw | Zinc plated |

Head type | Hexagon washer head |

Approval | ETA-11/0309 |

Type description | W-UR F 10 SymCon, hexagonal bolt |

| Designation | Fixture thickness tfix [mm] | Total length L [mm] | Embedment depth hnom [mm] | Nominal drill diameter d0 [mm] | Drill hole depth h1 [mm] | Approval ETA multiple attachment |

| W-UR F 10 x 50 SymCon | 10/-/- | 50 | 40/-/- | 10 | 50 (+tfix)/60 (+tfix)/80 (+tfix) | ETA-11/0309 |

| W-UR F 10 x 80 SymCon | 40/30/10 | 80 | 40/50/70 |

| Performance data for individual fixing point | |||||

| Anchor diameter [mm] | Würth W-UR 10 Symcon | ||||

| Admissible centric tension load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), s ≥ 135 mm c ≥ 70 mm) zinc-plated steel | Nadm [kN] = C20/252) | 30°C2)/50°C3) | 2,6 | 2,6 |

| 50°C2)/80°C3) | 2,4 | 2,4 | |||

| Compressive zone (uncracked concrete C20/252) s ≥ 135 mm c ≥ 70 mm) zinc-plated steel | 30°C2)/50°C3) | 2,6 | 2,6 | ||

| 50°C2)/80°C3) | 2,6 | 2,6 | |||

| Admissible shear load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), c ≥ 450 mm) zinc-plated steel | Vadm [kN] = C20/25 | 30°C2)/50°C3) | 5,4 | 5,0 |

| Compressive zone (uncracked concrete C20/252), c ≥ 450 mm) zinc-plated steel | 30°C2)/50°C3) | 5,4 | 5,0 | ||

| Admissible bending moment | Madm [Nm] | 30°C2)/50°C3) | 2,5 | ||

| 50°C2)/80°C3) | 2,14 | ||||

| Characteristic values | |||||

| Minimum spacing | smin [mm] | 50 | |||

| Spacing | scr,N [mm] | 135 | |||

| Minimum edge distance | cmin [mm] | 60 | |||

| Edge distance | ccr,N [mm] | 70 | |||

| Minimum member thickness | hmin ≥ [mm] | 110 | |||

| Nominal drill diameter | d0 [mm] | 10,0 | |||

| Diameter of cutting edges | dcut ≤ [mm] | 10,45 | |||

| Drill hole depth | h1 ≥ [mm] | 80 | |||

| Length of anchor in drill hole | hnom ≥ [mm] | 70 | |||

| Through hole in the member being connected | df ≤ [mm] | 10,5 | |||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and shear loads, please refer to ETAG 020 Appendix C 2) Maximum long-term temperature 3) Maximum short-term temperature | |||||

| Performance data: Hollow-core prestressed concrete ceilings Multiple attachment of non-load-bearing systems | |||||

| Anchor diameter | [mm] | W-UR 10 SymCon | |||

| Mirror thickness | du [mm] | 25 | 30 | 35 | 40 |

| Hollow-core prestressed concrete1) Fadm ≥ C30/37 [kN] | 30°C2)/50°C3) | 0,4 | 0,8 | 1,2 | 1,6 |

| 50°C2)/80°C3) | |||||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and shear loads, please refer to ETAG 020 Appendix C 2) Maximum long-term temperature 3) Maximum short-term temperature | |||||

| Performance data: Masonry4) Multiple attachment of non-load-bearing systems (temperature range 50°C2)/80°C3)) For other types of brick, raw densities, minimum compressive strength, edge and axis distances or temperature ranges, please refer to the approval ETA-11/0309 | |||||

| Brick type | Brick format [mm] | Raw density class [kg/dm3] | Minimum compressive strength [N/mm2] | Fadm [kN]1)5) (for individual anchors or an anchor group) W-UR 10 SymCon | |

| Effective anchorage depth | hnom [mm] | 50 | 70 | ||

| Lightweight concrete solid brick V, EN 771-3, DIN 18152-100 e.g. BisoBims, Bisotherm | ≥NF (≥240x115x71) | ≥1.0 | 2 | 0,21 | - |

| 4 | 0,43 | - | |||

| ≥3DF (≥240x175x71) | 2 | - | 0,11 | ||

| 4 | - | 0,21 | |||

| Vertically perforated brick HLz6), EN 771-1, DIN 105 e.g. Wienerberger, Schlagmann | ≥2DF (≥240x115x113) | ≥1.2 | 10 | - | 0,34 |

| 20 | - | 0,57 | |||

| ≥12DF (≥373x240x238) | 6 | - | 0,34 | ||

| 8 | - | 0,43 | |||

| 10 | - | 0,57 | |||

| Vertically perforated brick POROTON T8-306)), EN 771-1, T8: Z-17.1-982 Wienerberger, Schlagmann | ≥248x300x249 | ≥0.6 | 4 | - | 0,17 |

| 6 | - | 0,26 | |||

| 8 | - | 0,26 | |||

| Hollow sand-lime brick KSL6), EN 771-2, DIN 106-1 e.g. Xella | ≥2DF (≥240x115x113) | ≥1.4 | 6 | - | 0,26 |

| 8 | - | 0,34 | |||

| 10 | - | 0,43 | |||

| 12 | - | 0,57 | |||

| ≥8DF (≥249x240x238) | 6 | - | 0,21 | ||

| 8 | - | 0,26 | |||

| 10 | - | 0,34 | |||

| 12 | - | 0,43 | |||

| Hollow concrete block made of lightweight concrete 3K Hbl, EN 771-3, DIN 181516) e.g. Liapor | ≥16DF (≥498x240x238) | ≥0.7 | 2 | - | 0,17 |

| 4 | - | 0,34 | |||

| 6 | - | 0,34 | |||

| Aerated concrete EN 771-4, DIN 4165 | ≥499x100x249 | ≥0.3 | 2 | - | 0,18 |

| 3 | - | 0,26 | |||

| 4 | - | 0,34 | |||

| 5 | - | 0,42 | |||

| 6 | - | 0,5 | |||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and shear loads, please refer to ETAG 020 Appendix C 2) Maximum long-term temperature 3) Maximum short-term temperature 4) For other types of brick, raw densities, minimum compressive strengths or temperature ranges, please refer to the approval ETA-11/0309. 5) The brick geometry should be compared with the approval ETA-11/0309. 6) If the drill hole is created through impact or hammer action, the permissible load must be determined by tests on the structure. | |||||

Installation parameters: Concrete and masonry | ||||

Anchor diameter [mm] | W-UR 10 SymCon | |||

Nominal drill diameter | d0 [mm] | 10 | ||

Drill cutting diameter | dcut ≤ [mm] | 10,45 | ||

Drill hole depth | h1 ≥ [mm] | 50 | 60 | 80 |

Embedment depth of the anchor sleeve | hnom [mm] | 40 | 50 | 70 |

Through hole in the attachment | df ≤ [mm] | 10,5 | ||