TiN 90° countersink DIN 335C

Conical countersink HSS, titanium-nitride

CNTSNK-CONI-MA-HSS-90DGR-TIN-D31MM

Art.-no. 069402031

EAN 4011231603515

Register now and access more than 125,000 products

Up to 30 % faster cutting speeds and 2-4x longer service life compared to blue ring

TiN coating

Burr- and chatter-free countersinking and deburring

Precision conical countersink with three cutting edges, precision-ground

Optimised flute geometry

Excellent chip formation and removal

Product packaging made from 100 % PCR (recycled plastic from household waste) and 100 % recyclable

Datasheets(X)

| |

Material to be processed | Steel, Cast metal |

Quality | ZEBRA-Premium |

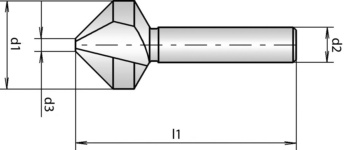

Spot-facer diameter (d1) | 31.0 mm |

Shank diameter (d2) | 12 mm |

Tip diameter (d3) | 4.2 mm |

Length (l1) | 71 mm |

Number of cutting edges (Z) | 3 PCS |

Standards | DIN 335 |

Form | C |

Cutting material | HSS |

Countersink angle | 90 Degree |

Surface | TiN |

Shank style | Cylindrical |

Service life (points system) | 3 of 4 points |

Countersinking speed (point system) | 3 of 4 points |

Countersinking quality (point system) | 2 of 4 points |

Versatility (points system) | 1 of 4 points |

Countersinking behaviour (point system) | 2 of 4 points |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, White cast iron |

| Assignment of conical countersink to screw standards | ||

| Conical countersink nominal diameter d1 | For countersunk head screws | For countersunk head screws |

| DIN EN ISO 10642 (formerly DIN 7991) | DIN EN ISO 2009, 2010, 7046, 7047 (formerly DIN 963,964,965,966) | |

| 6.3 mm | M3 | M3 |

| 8.3 mm | M4 | - |

| 10.4 mm | M5 | M4, M5 |

| 12.4 mm | M6 | M6 |

| 16.5 mm | M8 | M8 |

| 20.5 mm | - | M10 |

| 25.0 mm | M10, M12 | M12 |

| 31.0 mm | M16 | - |

| Legend |

| vc = cutting speed [m/min] |

| f = feed (mm/r) |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| For dia. 16.5-31 | ||||||

| Material designation | Tensile strength | vc | f | |||

| Dia. 16.5 | Dia. 20.5 | Dia. 25 | Dia. 31 | |||

| Steels | ||||||

| General structural steels | ≤ 500 N/mm² | 35 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 1,000 N/mm² | 33 | 0,110 | 0,130 | 0,150 | 0,170 | |

| Unalloyed quenched and tempered steels | ≤ 700 N/mm² | 35 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 850 N/mm² | 33 | 0,170 | 0,180 | 0,210 | 0,240 | |

| ≤ 1,000 N/mm² | 22 | 0,110 | 0,130 | 0,150 | 0,170 | |

| Alloyed quenched and tempered steels | ≤ 1,000 N/mm² | 17 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 1,400 N/mm² | 13 | 0,110 | 0,130 | 0,150 | 0,170 | |

| Nitriding steels | ≤ 1,000 N/mm² | 17 | 0,110 | 0,130 | 0,150 | 0,170 |

| ≤ 1,400 N/mm² | 13 | 0,070 | 0,080 | 0,090 | 0,120 | |

| Tool steels | ≤ 850 N/mm² | 19 | 0,110 | 0,130 | 0,150 | 0,170 |

| ≤ 1,400 N/mm² | 17 | 0,070 | 0,080 | 0,090 | 0,120 | |

| High-speed steels | ≤ 1,400 N/mm² | 17 | 0,070 | 0,080 | 0,090 | 0,120 |

| Cast metals | ||||||

| Cast iron | ≤ 240 HB | 19 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 350 HB | 17 | 0,170 | 0,180 | 0,210 | 0,240 | |

| Spheroidal graphite and malleable iron | ≤ 240 HB | 17 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 350 HB | 17 | 0,170 | 0,180 | 0,210 | 0,240 | |

| Chilled cast iron | ≤ 350 HB | 12 | 0,070 | 0,080 | 0,090 | 0,120 |

| Cutting values | ||||||

| For dia. 6.3-12.4 | ||||||

| Material designation | Tensile strength | vc | f | |||

| Dia. 6.3 | Dia. 8.3 | Dia. 10.4 | Dia. 12.4 | |||

| Steels | ||||||

| General structural steels | ≤ 500 N/mm² | 35 | 0,120 | 0,130 | 0,135 | 0,150 |

| ≤ 1,000 N/mm² | 33 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Unalloyed quenched and tempered steels | ≤ 700 N/mm² | 35 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 850 N/mm² | 33 | 0,120 | 0,130 | 0,135 | 0,150 | |

| ≤ 1,000 N/mm² | 22 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Alloyed quenched and tempered steels | ≤ 1,000 N/mm² | 17 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 1,400 N/mm² | 13 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Nitriding steels | ≤ 1,000 N/mm² | 17 | 0,070 | 0,080 | 0,090 | 0,100 |

| ≤ 1,400 N/mm² | 13 | 0,040 | 0,050 | 0,060 | 0,060 | |

| Tool steels | ≤ 850 N/mm² | 19 | 0,070 | 0,080 | 0,090 | 0,100 |

| ≤ 1,400 N/mm² | 17 | 0,040 | 0,050 | 0,060 | 0,060 | |

| High-speed steels | ≤ 1,400 N/mm² | 17 | 0,040 | 0,050 | 0,060 | 0,060 |

| Cast metals | ||||||

| Cast iron | ≤ 240 HB | 19 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 350 HB | 17 | 0,120 | 0,130 | 0,140 | 0,150 | |

| Spheroidal graphite and malleable iron | ≤ 240 HB | 17 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 350 HB | 17 | 0,120 | 0,130 | 0,140 | 0,150 | |

| Chilled cast iron | ≤ 350 HB | 12 | 0,040 | 0,050 | 0,060 | 0,060 |