Spacing assembly screw AMO® III 11.5

Amo III type 2 steel zinc plated RW 40

SCR-RW40-(A2K)-11,5X182

AMO III

Register now and access more than 125,000 products

- Mechanically interlocking, removable anchorage with no expansion pressure

- Load-bearing capacity is retained even under thermal stress

- Immediate load-bearing capacity - no waiting after installation

- Tested fire resistance rating of 120 minutes

- Tested break-in resistant properties for plastic windows of RC2

- Saves time - no anchors required

- Short installation times, no setting tools are required

- AW drive for longer bit service life, improved power transmission and no ejection forces

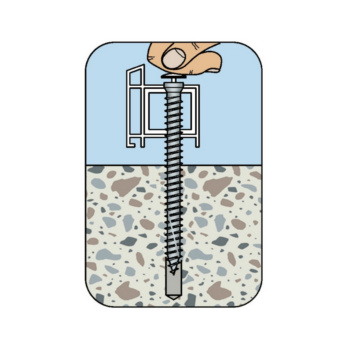

- In-place installation

- Mechanical interlocking for high load-bearing capacity

- Removable

- Virtually no expansion forces during installation

- Fire protection test report no. 3174/0649-2 dated 12 January 2000

- Break-in resistance RC2. Expert report by ift Rosenheim dated 21 November 2005, no. 255 29923

- Test of suitability for attaching a window to a brick masonry building structure conducted by ift Rosenheim. Test report no. 105 30599 dated 10 July 2006

It is important to check that the members are correctly installed for the specific construction conditions (e.g. weight of window casement, surface properties, hole pattern in the brick). Fall-proof glazing as specified in the German technical rules for safety glazing (TRAV) or DIN 18008-4 may only be attached with the AMO Combi screw if appropriate individual approval has been obtained before installation starts.

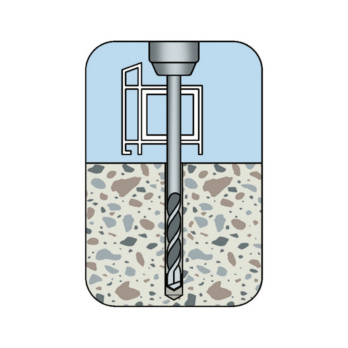

Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

Align window frames using alignment clamps or Amo® Bag

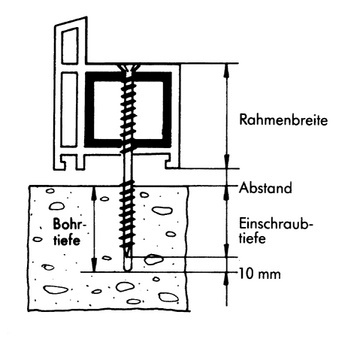

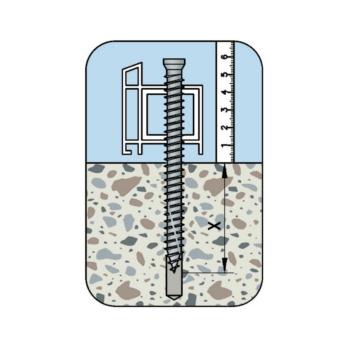

Screw length = frame width + spacing + length of thread engagement (see also 55.2 Amo® III 11.5 mm)

Create the drill hole

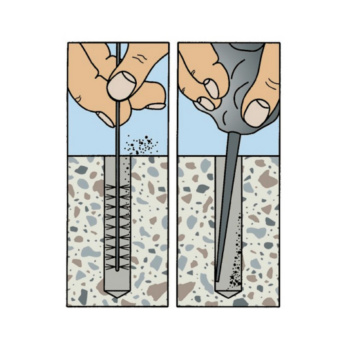

Clean the drill hole

Clean the drill hole

Align and affix the window frame

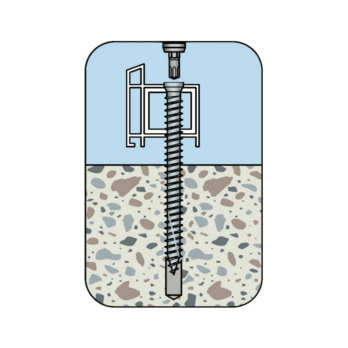

Screw in the screw

Press on cover cap

- Fire protection test report no. 3174/0649-2 dated 12 January 2000

- Break-in resistance RC2. Expert report by ift Rosenheim dated 21 November 2005, no. 255 29923

- Test of suitability for attaching a window to a brick masonry building structure conducted by ift Rosenheim. Test report no. 105 30599 dated 10 July 2006

Datasheets(X)

- Tension-free stand-off installation for all frame materials and masonry types

- Installation of window and door frames with pre-drilled mounting hole dia. 10 mm

Guidelines for planning and executing the installation of windows and house doors

The fixture must safely transfer all standard forces affecting the window to the structure and the foundation. The total load must therefore be calculated from e.g. the window load, wind load and live load (see DIN 1055). The currently applicable building regulations stipulate that buildings and their components must be planned in such a way that they do not endanger human life and health or pose a risk to public safety. Attachment of the windows must also comply with this criterion.

When securing window walls compliant with the former DIN 18056 standard or elements with a surface area in excess of 9 m2 and fall-proof glazing as specified in the German technical rules for safety glazing (TRAV) or DIN 18008-4, the following must be observed

The DIN 18056 standard applied to window walls with a minimum surface area of 9 m2 and a minimum side length of 2 m on the shortest side. Anchors with construction product approval, European Technical Approval or with individual approval should be used for this application. Similarly, only anchors with construction product approval, European Technical Approval or with individual approval must be used to attach fall-proof glazing as specified in the German technical rules for safety glazing (TRAV) or DIN 18008-4.

| |

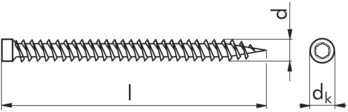

Length (l) | 182 mm |

Thread diameter (d) | 11.5 mm |

Material | Steel |

Surface | Zinc plated |

Head type | Socket head |

Head diameter (d(h/k)) | 11.5 mm |

Internal drive | RW40 |

Thread type | Metric thread |

Shape of tip | Tip |

| Performance data | |||

| Anchor type | Dia. 11.5 | ||

| Fire resistance grading concrete compressive strength min. C20/25 and max. C50/60 | Transverse tension or diagonal tensile force to 30° | F30 [kN] | 0,50 |

| F60 [kN] | 0,50 | ||

| F90 [kN] | 0,50 | ||

| F120 [kN] | 0,50 | ||

| Characteristic values | ||||

| General | minimum edge distance | Concrete | cmin [mm] | 50 |

| Sand-lime brick, solid brick, vertically perforated brick (min. 2 walls), pumice, lightweight concrete, aerated concrete | 60 | |||

| minimum engagement length | Concrete | hnom ≥ [mm] | 30 | |

| Sand-lime brick, solid brick | 50 | |||

| Vertically perforated brick (min. 2 walls), pumice, lightweight concrete, aerated concrete | 60 | |||

| Nominal drill bit diameter | Concrete | d0 [mm] | 10,0 | |

| Sand-lime brick, solid brick, vertically perforated brick (min. 2 walls), pumice, lightweight concrete | 10,0 | |||

| Aerated concrete | No pre-drilling required | |||

| Drill hole depth | h1 [mm] | Engagement length + 10 mm + any existing plaster coat | ||

| Burglary resistance WK21) | minimum edge distance | Concrete ≥ B15, vertically perforated brick HLz 12, solid brick Mz, solid sand-lime brick KS, hollow sand-lime brick KSL, solid bricks and solid blocks of lightweight concrete V/Vbl | cmin [mm] | 60 |

| Aerated concrete PP4 | 100 | |||

| Nominal drill bit diameter | Concrete ≥ B15 | d0 [mm] | 10,0 | |

| Vertically perforated brick HLz 12, solid brick Mz, solid sand-lime brick KS, hollow sand-lime brick KSL, solid bricks and solid blocks of lightweight concrete V/Vbl | 10,0 | |||

| Aerated concrete PP4 | in stone: no predrilling required, in window lintel 10.0 | |||

| Wall thickness | d ≥ [mm] | 240 | ||

| Engagement length | hnom ≥ [mm] | 60 | ||

| Drill hole depth | h1 [mm] | Engagement length + 10 mm + any existing plaster coat | ||

| 1) The compressive strength of the masonry must at least meet the requirements of masonry strength class M11 as defined in DIN 1053-2. No point of the structural connection joint between reveal and blind frame profile must exceed 25 mm. The minimum thickness of the steel wall is 1.5 mm. | ||||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!