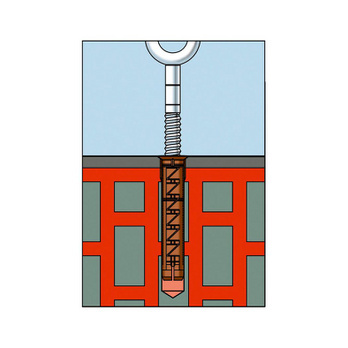

Scaffolding eyelet screw W-GS SymCon®

Scaffold eyelet screw, W-GS SymCon GS

BLT-EYE-FRAME-(A0K)-6.8-10X330

Register now and access more than 125,000 products

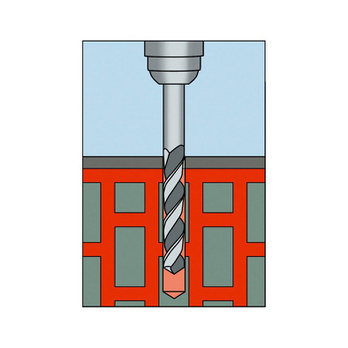

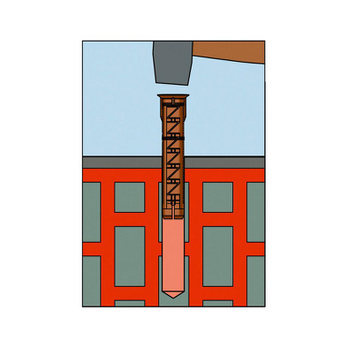

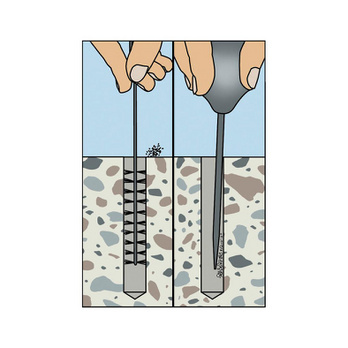

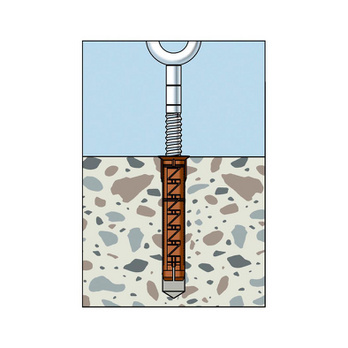

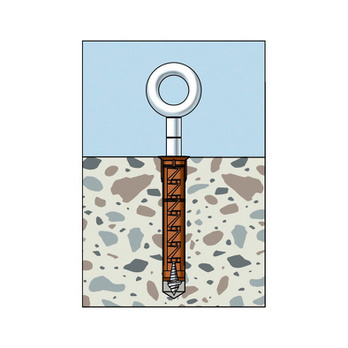

SymCon screw

- The dimensions of the anchor screw enable safe subsequent expansion properties

- SymCon screw: Screwing in the SymCon screw ensures optimum compression of the anchor sleeve plastic (virtually no undercutting), thereby improving the load transfer

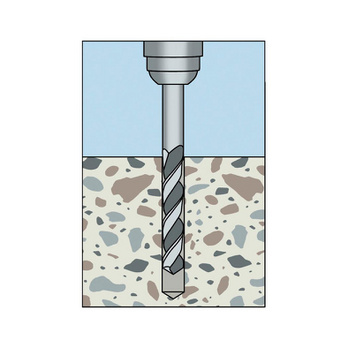

More than 19 tested anchoring bases

Every single screw is marked with a batch number — increased safety

Useful information:

The user must conduct test loading at each place of use, in accordance with German safety regulation BGI/GUV-I 663, item 4.6.3

When anchoring in solid brick and solid sand-lime brick, we recommend performing pull-out tests due to differences in brick manufacturing

Datasheets(X)

- < 2 years

- W-UR, W-UR F can be anchored in the following anchoring bases: Standard concrete, masonry walls (solid brick, solid sand-lime brick, vertically perforated brick, perforated sand-lime brick, hollow lightweight concrete blocks, solid bricks and blocks made of lightweight concrete, concrete bricks)

- Suitable for attaching façade scaffolding, staging, scaffolding systems etc.

Screw diameter (ds) | 10 mm |

Screw length | 330 mm |

Embedding depth (h s) | 100 mm |

Performance data: concrete, anchors in a redundant non-structural system | |||

Anchor diameter | [mm] | W-UR 14 SymCon | |

Embedment depth of the anchor sleeve | hnom [mm] | 100 | |

| Centric tension load1) for individual anchors or an anchor group | Nadm = C12/15 [kN] | 30°C2)/50°C3) | 2.4 (2.1)4) |

| 50°C2)/80°C3) | 2.4 (2.1)4) | ||

| Nadm ≥ C16/20 [kN] | 30°C2)/50°C3) | 3.2 (2.1)4) | |

| 50°C2)/80°C3) | 3.2 (2.1)4) | ||

| Minimum member thickness | hmin | [mm] | 140 |

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For information on combining tensile and shear loads, please refer to ETAG 020 Appendix C. 2) Maximum long-term temperature 3) Maximum short-term temperature 4) Number of attachment points = 3 and at least 1 anchor per attachment point results in a load per attachment point of Nadm ≤ 2.1 kN or number of attachment points ≥ 4 and at least 1 anchor per fixing point results in a load per attachment point of Nadm ≤ 2.4 kN or 3.2 kN (depending on concrete strength and temperature range). | |||

Performance data: Masonry4), anchors in a redundant non-structural system (temperature range 50°C2) /80°C3)) For other types of stone, raw densities, minimum compressive strengths, edge distances and spacings or temperature ranges, please refer to approval ETA-11/0309 | ||||

Stone type | Brick format [mm] | Raw density class [kg/dm3] | Minimum compressive strength [N/mm2] | Nadm [kN] 1) 5) (Centric tension load for individual anchors) |

Effective anchorage depth | hnom [mm] | 100 | ||

Masonry brick Mz, EN 771-1, DIN 105 | ≥ 3DF (≥ 240 x 115 x 113) | ≥ 1.8 | 10 | 1,0 |

| 20 | 1,57 | |||

Solid calcium silicate block Silka XL Basic, Silka XL Plus, EN 771-2, DIN 106, Z-17.1-997 | ≥ NF (≥ 248 x 175 x 498) | ≥ 2.0 | 10 | 0,86 |

| 20 | 1,29 | |||

| 28 | 1,86 | |||

Solid brick normal weight concrete Vbn, EN 771-3, DIN 18153 | ≥ NF (≥ 240 x 115 x 71) | ≥ 2.0 | 10 | 0,57 |

| 20 | 0,86 | |||

| 28 | 1,14 | |||

Solid brick normal weight concrete V, EN 771-3, DIN 18152-100 e.g. BisoBims Classic, Bisotherm | ≥ 3DF (≥ 240 x 175 x 113) | ≥ 2.0 | 10 | 1,14 |

| 20 | 1,57 | |||

Solid brick lightweight concrete V, EN 771-3, DIN 18152-100 e.g. BisoBims | ≥ NF (≥ 240 x 115 x 71) | ≥ 1.0 | 2 | 0,34 |

| 4 | 0,57 | |||

Vertically perforated brick HLz6), EN 771-1, DIN 105 e.g. Wienerberger, Schlagmann | ≥ 12DF (≥ 373 x 240 x 238) | ≥ 1.2 | 6 | 0,43 |

| 8 | 0,57 | |||

| 10 | 0,71 | |||

Vertically perforated brick HLz T14-24.06), EN 771-1, Z-17.1-651 e.g. Wienerberger | ≥ 10DF (≥ 308 x 240 x 249) | ≥ 0.7 | 6 | 0,17 |

Vertically perforated brick POROTON T8-306), POROTON T9-306), EN 771-1, T8: Z-17.1-982, T9: Z-17.1-674 Wienerberger, Schlagmann | ≥ 248 x 300 x 249 | ≥ 0.6 | 6 | 0,43 |

| 8 | 0,57 | |||

Hollow calcium silicate block KSL6), EN 771-2, DIN 106-1 e.g. Xella | ≥ 8DF (≥ 249 x 240 x 238) | ≥ 1.4 | 6 | 0,34 |

| 8 | 0,43 | |||

| 10 | 0,57 | |||

| 12 | 0,71 | |||

Hollow concrete block made of lightweight concrete 3K Hbl, EN 771-3, DIN 181516) e.g. Liapor | ≥ 16DF (≥ 498 x 240 x 238) | ≥ 0.7 | 2 | 0,14 |

| 4 | 0,26 | |||

| 6 | 0,43 | |||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and shear loads, please refer to ETAG 020 Annex C 2) Maximum long-term temperature 3) Maximum short-term temperature 4) For other types of stone, raw densities, minimum compressive strengths or temperature ranges, please refer to approval ETA-11/0309. 5) The brick geometry should be compared with approval ETA-08/0190. 6) If the drill hole is created through impact or hammer action, the admissible load must be determined by tests on the structure. | ||||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!