NC machine reamer HSCO WN, H7 universal

NC machine reamer H7 HSCo WN

MAREAMER-HSCO-DIN1835A-H7-D2,5-L57/14

Art.-no. 0620100250

EAN 4052712404290

Register now and access more than 125,000 products

- NC-compliant design similar to DIN 212 (shape D) with even shaft diameter for standardised mounting, especially in hydraulic expansion chucks or high-precision chucks.

- Twisted flute design

- Left-hand spiral for maximum concentricity and process reliability

- No special mounts are required

Datasheets(X)

- Especially suited for interrupted cuts such as longitudinal grooves and cross holes

- Materials to be processed: Suitable for all ferrous metals, non-ferrous metals and steel

Please refer to the machining manual for the correct undersize for pre-drilling.

| |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Copper, Brass, Aluminium, Plastic |

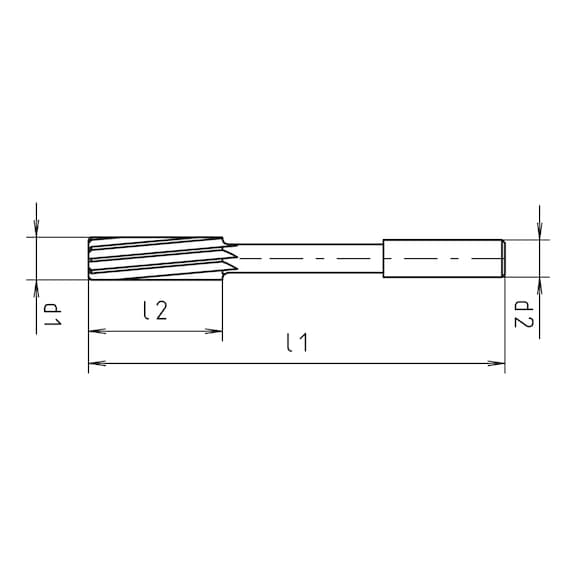

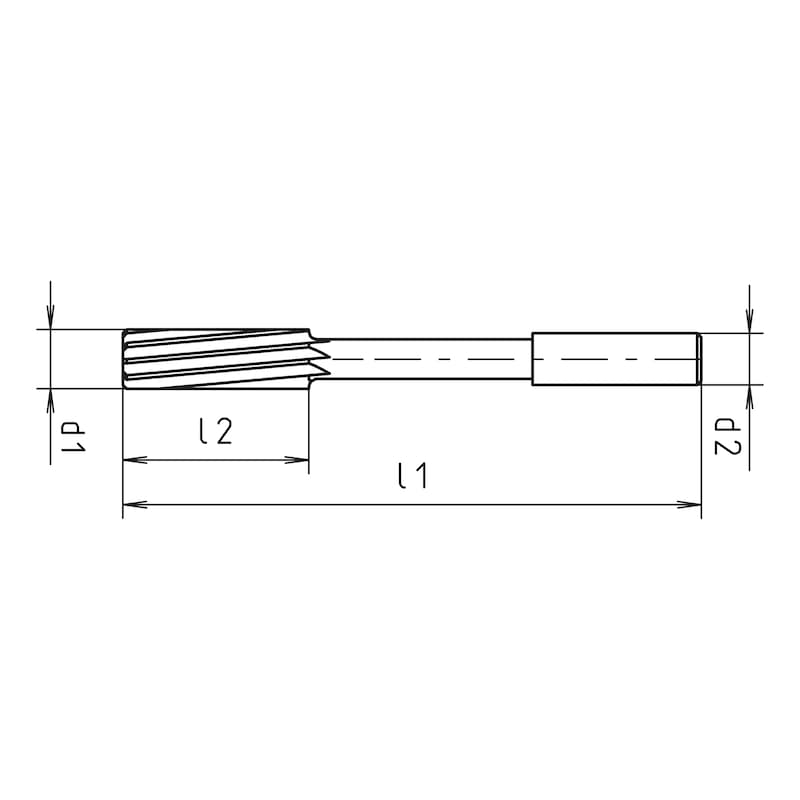

Cutting edge diameter (d1) | 2.50 mm |

Shank diameter (d2) | 3.0 mm |

Length (l1) | 57 mm |

Cutting edge length (l2) | 14 mm |

Projecting length (l3) | 28 mm |

Number of cutting edges (Z) | 4 PCS |

Core hole diameter | 2.40 mm |

Standards | DIN 212 similar |

Form | B |

Cutting material | HSCo |

Surface | Uncoated |

Groove type | Left-hand twist, 8° |

Shank style | Cylindrical DIN 6535-HA |

Tolerance of fit | H7 |

Max. drilling depth (D) | 8xD |

Hole type | Clearance hole |

Coolant supply | External |

Service life (points system) | 3 of 4 points |

Versatility (points system) | 4 of 4 points |

Tolerance of cutting edge diameter | h7 |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Titanium, Titanium alloys, Copper, Brass, Aluminium, Plastics |

| Cutting values | ||||||||

| For dia. 1.5-9.9 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| from | to | Dia. 1.5-1.9 | Dia. 2-4.9 | Dia. 5-7.9 | Dia. 8-9.9 | |||

| Steels | ||||||||

| General structural steels | < 500 N/mm² | O/E | 10 | 12 | 0,060 | 0,080 | 0,100 | 0,130 |

| 500-850 N/mm² | O/E | 6 | 8 | 0,060 | 0,080 | 0,100 | 0,130 | |

| Carbon steels | < 850 N/mm² | O/E | 6 | 8 | 0,060 | 0,080 | 0,100 | 0,130 |

| 850-1,000 N/mm² | O/E | 4 | 6 | 0,048 | 0,064 | 0,080 | 0,100 | |

| Unalloyed quenched and tempered steels | < 700 N/mm² | O/E | 8 | 10 | 0,060 | 0,080 | 0,100 | 0,130 |

| 700-850 N/mm² | O/E | 6 | 8 | 0,060 | 0,080 | 0,100 | 0,130 | |

| 850-1,000 N/mm² | O/E | 4 | 6 | 0,048 | 0,064 | 0,080 | 0,100 | |

| Alloyed quenched and tempered steels | 850-1,000 N/mm² | O/E | 3 | 5 | 0,048 | 0,064 | 0,080 | 0,100 |

| 1,000-1,200 N/mm² | O/E | 3 | 5 | 0,048 | 0,064 | 0,080 | 0,100 | |

| Unalloyed case-hardening steels | < 750 N/mm² | O/E | 6 | 8 | 0,060 | 0,080 | 0,100 | 0,130 |

| Alloyed case-hardening steels | < 1,000 N/mm² | O/E | 4 | 6 | 0,048 | 0,064 | 0,080 | 0,100 |

| 1,000-1,200 N/mm² | O/E | 3 | 5 | 0,048 | 0,064 | 0,080 | 0,100 | |

| Nitriding steels | < 1,000 N/mm² | O/E | 4 | 6 | 0,048 | 0,064 | 0,080 | 0,100 |

| 1,000-1,200 N/mm² | O/E | 3 | 5 | 0,048 | 0,064 | 0,080 | 0,100 | |

| Tool steels | < 850 N/mm² | O/E | 6 | 8 | 0,060 | 0,080 | 0,100 | 0,130 |

| 850-1,100 N/mm² | O/E | 4 | 6 | 0,048 | 0,064 | 0,080 | 0,100 | |

| 1,100-1,400 N/mm² | O/E | 3 | 5 | 0,048 | 0,064 | 0,080 | 0,100 | |

| High-speed steels | 850-1,200 N/mm² | O/E | 4 | 6 | 0,048 | 0,064 | 0,080 | 0,100 |

| Wear-resistant constructional steel | 1,350 N/mm² | E | 3 | 5 | 0,048 | 0,064 | 0,080 | 0,100 |

| Spring steels | < 1,200 N/mm² | E | 3 | 5 | 0,048 | 0,064 | 0,080 | 0,100 |

| Stainless steels | ||||||||

| Sulphurated stainless steels | < 700 N/mm² | E | 6 | 8 | 0,070 | 0,080 | 0,100 | 0,120 |

| Austenitic stainless steels | < 700 N/mm² | E | 6 | 8 | 0,070 | 0,080 | 0,100 | 0,120 |

| < 850 N/mm² | E | 4 | 6 | 0,050 | 0,064 | 0,080 | 0,095 | |

| Martensitic stainless steels | < 1,100 N/mm² | E | 4 | 6 | 0,050 | 0,064 | 0,080 | 0,095 |

| Special alloys | < 1,200 N/mm² | E | 3 | 5 | 0,048 | 0,064 | 0,080 | 0,100 |

| Titanium, titanium alloys | < 850 N/mm² | E | 4 | 6 | 0,048 | 0,064 | 0,080 | 0,100 |

| Cast metals | ||||||||

| Cast iron | < 180 HB | T/O | 8 | 10 | 0,108 | 0,144 | 0,180 | 0,200 |

| > 180 HB | T/O | 4 | 6 | 0,072 | 0,096 | 0,120 | 0,150 | |

| Spheroidal graphite, malleable iron | > 180 HB | T/E | 8 | 10 | 0,108 | 0,144 | 0,180 | 0,200 |

| > 260 HB | T/E | 6 | 8 | 0,090 | 0,120 | 0,150 | 0,180 | |

| Non-ferrous metals | ||||||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 15 | 20 | 0,090 | 0,120 | 0,160 | 0,200 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 10 | 15 | 0,090 | 0,120 | 0,160 | 0,200 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 10 | 12 | 0,090 | 0,120 | 0,160 | 0,200 |

| Magnesium, magnesium alloys | < 280 N/mm² | E | 15 | 20 | 0,090 | 0,120 | 0,160 | 0,200 |

| Low-alloy copper | < 350 N/mm² | E | 8 | 12 | 0,090 | 0,120 | 0,150 | 0,180 |

| Short-chipping brass | < 600 N/mm² | T/E | 12 | 14 | 0,120 | 0,160 | 0,200 | 0,250 |

| Long-chipping brass | < 600 N/mm² | T/E | 10 | 12 | 0,120 | 0,160 | 0,200 | 0,250 |

| Short-chipping bronze | < 600 N/mm² | T/E | 12 | 14 | 0,120 | 0,160 | 0,200 | 0,250 |

| 650-850 N/mm² | T/E | 12 | 14 | 0,120 | 0,160 | 0,200 | 0,250 | |

| Long-chipping bronze | < 850 N/mm² | T/E | 10 | 12 | 0,120 | 0,160 | 0,200 | 0,250 |

| 850-1,200 N/mm² | T/E | 10 | 12 | 0,120 | 0,160 | 0,200 | 0,250 | |

| Graphite | - | T | 8 | 10 | 0,090 | 0,120 | 0,150 | 0,180 |

| Key |

| O = oil |

| E = emulsion |

| T = dry |

| vc = cutting speed [m/min] |

| fz = feed [mm/r] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values | |||||||

| For dia. 10-20 | |||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||

| from | to | Dia. 10-14.9 | Dia. 15-19.9 | Dia. 20 | |||

| Steels | |||||||

| General structural steels | < 500 N/mm² | O/E | 10 | 12 | 0,150 | 0,200 | 0,250 |

| 500-850 N/mm² | O/E | 6 | 8 | 0,150 | 0,200 | 0,250 | |

| Carbon steels | < 850 N/mm² | O/E | 6 | 8 | 0,150 | 0,200 | 0,250 |

| 850-1,000 N/mm² | O/E | 4 | 6 | 0,100 | 0,150 | 0,200 | |

| Unalloyed quenched and tempered steels | < 700 N/mm² | O/E | 8 | 10 | 0,150 | 0,200 | 0,250 |

| 700-850 N/mm² | O/E | 6 | 8 | 0,150 | 0,200 | 0,250 | |

| 850-1,000 N/mm² | O/E | 4 | 6 | 0,100 | 0,150 | 0,200 | |

| Alloyed quenched and tempered steels | 850-1,000 N/mm² | O/E | 3 | 5 | 0,100 | 0,150 | 0,200 |

| 1,000-1,200 N/mm² | O/E | 3 | 5 | 0,100 | 0,150 | 0,200 | |

| Unalloyed case-hardening steels | < 750 N/mm² | O/E | 6 | 8 | 0,150 | 0,200 | 0,250 |

| Alloyed case-hardening steels | < 1,000 N/mm² | O/E | 4 | 6 | 0,100 | 0,150 | 0,200 |

| 1,000-1,200 N/mm² | O/E | 3 | 5 | 0,100 | 0,150 | 0,200 | |

| Nitriding steels | < 1,000 N/mm² | O/E | 4 | 6 | 0,100 | 0,150 | 0,200 |

| 1,000-1,200 N/mm² | O/E | 3 | 5 | 0,100 | 0,150 | 0,200 | |

| Tool steels | < 850 N/mm² | O/E | 6 | 8 | 0,150 | 0,200 | 0,250 |

| 850-1,100 N/mm² | O/E | 4 | 6 | 0,100 | 0,150 | 0,200 | |

| 1,100-1,400 N/mm² | O/E | 3 | 5 | 0,100 | 0,150 | 0,200 | |

| High-speed steels | 850-1,200 N/mm² | O/E | 4 | 6 | 0,150 | 0,150 | 0,200 |

| Wear-resistant constructional steel | 1,350 N/mm² | E | 3 | 5 | 0,100 | 0,150 | 0,200 |

| Spring steels | < 1,200 N/mm² | E | 3 | 5 | 0,100 | 0,150 | 0,200 |

| Stainless steels | |||||||

| Sulphurated stainless steels | < 700 N/mm² | E | 6 | 8 | 0,130 | 0,165 | 0,200 |

| Austenitic stainless steels | < 700 N/mm² | E | 6 | 8 | 0,130 | 0,165 | 0,200 |

| < 850 N/mm² | E | 4 | 6 | 0,100 | 0,130 | 0,160 | |

| Martensitic stainless steels | < 1,100 N/mm² | E | 4 | 6 | 0,100 | 0,130 | 0,160 |

| Special alloys | < 1,200 N/mm² | E | 3 | 5 | 0,100 | 0,150 | 0,200 |

| Titanium, titanium alloys | < 850 N/mm² | E | 4 | 6 | 0,100 | 0,150 | 0,200 |

| Cast metals | |||||||

| Cast iron | < 180 HB | T/O | 8 | 10 | 0,230 | 0,250 | 0,300 |

| > 180 HB | T/O | 4 | 6 | 0,170 | 0,200 | 0,250 | |

| Spheroidal graphite, malleable iron | > 180 HB | T/E | 8 | 10 | 0,230 | 0,250 | 0,300 |

| > 260 HB | T/E | 6 | 8 | 0,200 | 0,200 | 0,250 | |

| Non-ferrous metals | |||||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 15 | 20 | 0,230 | 0,260 | 0,300 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 10 | 15 | 0,230 | 0,260 | 0,300 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 10 | 12 | 0,230 | 0,260 | 0,300 |

| Magnesium, magnesium alloys | < 280 N/mm² | E | 15 | 20 | 0,230 | 0,260 | 0,300 |

| Low-alloy copper | < 350 N/mm² | E | 8 | 12 | 0,200 | 0,250 | 0,300 |

| Short-chipping brass | < 600 N/mm² | T/E | 12 | 14 | 0,300 | 0,350 | 0,400 |

| Long-chipping brass | < 600 N/mm² | T/E | 10 | 12 | 0,300 | 0,350 | 0,400 |

| Short-chipping bronze | < 600 N/mm² | T/E | 12 | 14 | 0,300 | 0,350 | 0,400 |

| 650-850 N/mm² | T/E | 12 | 14 | 0,300 | 0,350 | 0,400 | |

| Long-chipping bronze | < 850 N/mm² | T/E | 10 | 12 | 0,300 | 0,350 | 0,400 |

| 850-1,200 N/mm² | T/E | 10 | 12 | 0,300 | 0,350 | 0,400 | |

| Graphite | - | T | 8 | 10 | 0,200 | 0,250 | 0,300 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!