Locking disc spring washer, shape M Spring steel hardened 420-510 HV10, zinc-flake coated

Steel zinc-flake silver type M

WSH-SER-M-(FLZN480H)-D21,0

Art.-no. 040120

EAN 4024835613477

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

- Type M (medium): up to and including screw connections of strength class 8.8 with normal head contact

- Protection type: Screw retainer

- Friction locking thanks to spring force

- Mechanical interlock thanks to specific surface stamping

- Protects the counter surface from damage (washer does not turn during installation)

- Minimal tightening torque distribution

Product information

Datasheets(X)

CAD data (available after login)

Application area

Machine and system construction, drive technology, conveyor technology, commercial vehicles, construction machines, vehicle construction, agricultural technology, the food industry etc.

| |

Suitable for screw thread | M20 |

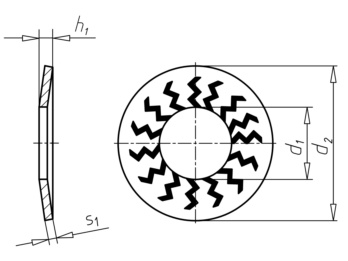

Internal diameter (d1) | 21 mm |

Outer diameter (d2) | 40 mm |

Height (h1) | 4.3 mm |

Thickness (s1) | 3 mm |

Material | Spring steel |

Min./max. Vickers hardness, HV | 420-510 HV |

Surface | Flake zinc silver |

RoHS-compliant | Yes |

Corrosion protection period | 720 h |

Form | M |

Locking device operating principle | Serrated lock washer |

Locking function | Embedding locking device |

Comparison of locking disc spring washers and lock washers | |

| Locking disc spring washer | Lock washer with no DIN standard |

| + Twice as secure: spring-secured friction fit and positive locking + Minimal tightening torque distribution + Application range up to approx. 350°C + Reusable + Protection of the counter surface; no turning | Without a DIN standard, lock washers become a safety risk! - Very high tightening torque distribution - Only suitable for locking screws 5.8 - In the worst case scenario, lock washers can wear through surfaces and thereby promote a drop in the preload force. - No protection against unscrewing - Lock washers are not reusable - Lock washers tend to expand (risk of breakage) - They turn during tightening and loosening -> This damages the surface/counter surface |