High-performance anchor with threaded bolt

High-performance anchor W-HAZ steel zn ptd. type B

ANC-(W-HAZ/B)-(A2K)-15-M10X111

Art.-no. 0905215102

EAN 4038898663034

Register now and access more than 125,000 products

- High load-bearing capacities

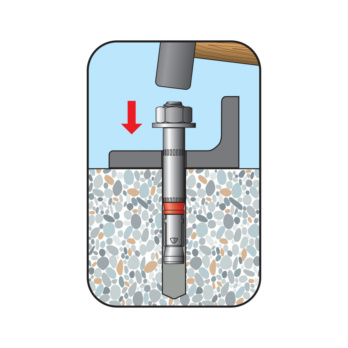

- Time-saving push-through installation

- Immediate load-bearing capacity — no waiting

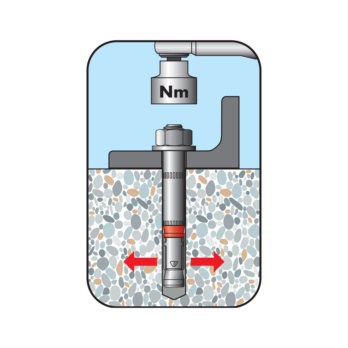

- Torque-controlled expanding galvanised steel anchor

- ETA-02/0031 for individual attachment, option 1, cracked and non-cracked concrete, seismic performance category C1 and C2

- Fire resistance: F30, F60, F90 and F120; exposure to fire according to DIN 1363-1:1999-10 (uniform temperature-time curve)

- Fire resistance: R30, R60, R90 and R120; TR020 (included in ETA-02/0031)

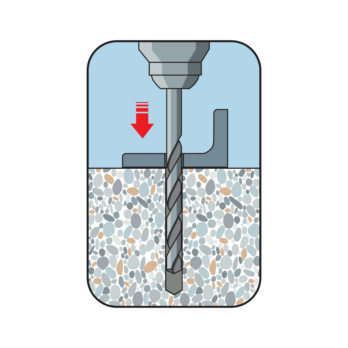

Create the drill hole

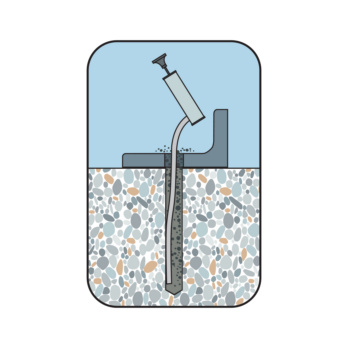

Clean the drill hole

- ETA-02/0031 for individual attachment, option 1, cracked and non-cracked concrete, seismic performance category C1 and C2

- Fire resistance: F30, F60, F90 and F120; exposure to fire according to DIN 1363-1:1999-10 (uniform temperature-time curve)

- Fire resistance: R30, R60, R90 and R120; TR020 (included in ETA-02/0031)

Datasheets(X)

CAD data (available after login)

Individual attachment with approval

Normal concrete C20/25 to C50/60 (cracked and non-cracked concrete, seismic performance category C1 and C2 for sizes M8–M20)

e.g. metal structures, metal profiles, brackets, base plates, supports, cable conduits, pipes, railings, machines etc.

Individual attachment without approval

Can be used in concrete < C20/25 and compression-proof natural stone

Approved only for use in dry indoor room conditions

Metric anchor diameter | M10 |

Anchor length (l) | 111 mm |

Max. attachment height (t fix) | 15 mm |

Width across flats | 17 mm |

Nominal drill-bit diameter (d 0) | 15 mm |

Drill hole depth (h 1) | 95 mm |

Effective anchoring depth (h ef) | 71 mm |

Torque during anchoring (T inst) | 50 Nm |

Through-hole in the component to be connected (d f) | 17 mm |

Material | Steel |

Surface | Zinc plated |

| Performance data | |||||||||

| Anchor diameter [mm] | M6 | M8 | M10 | M12 | M16 | M16L | M20 | ||

| Admissible centric tension load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), s ≥ 3 hef, c ≥ 1.5 hef) | Nadm [kN] = C20/252) | 2,4 | 5,7 | 7,6 | 12,3 | 17,1 | 21,1 | 24,0 |

| Compressive zone (uncracked concrete C20/252)) minimum spacing and edge distances (scr,sp ≥ 5 hef, ccr, sp ≥ 2.5 hef) | 7,6 | 9,5 | 14,3 | 17,2 | 24,0 | 29,6 | 33,5 | ||

| Admissible shear load1) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/252), c ≥ 10 hef) W-HAZ-B/S/W-HAZ-S/S and W-HAZ-SK/S | Vadm [kN] = C20/252) | 9.1/10.1 | 14.0/15.9 | 20.5/20.5 | 24.5/24.5 | 34.3/34.3 | 42.3/42.3 | 47.9/47.9 |

| Compressive zone (uncracked concrete C20/252), c ≥ 10 hef) W-HAZ-B/S/W-HAZ-S/S and W-HAZ-SK/S | 9.1/10.1 | 14.0/17.1 | 20.7/27.5 | 34.3/34.3 | 48.0/48.0 | 52.1/59.2 | 67.1/67.1 | ||

| Admissible bending moment | Madm [Nm] | 6,9 | 17,1 | 34,3 | 60 | 152 | 152 | 296,6 | |

| Admissible load when exposed to fire (R30, R60, R90, R120) see European Technical Approval ETA-02/0031 | |||||||||

| Fire resistance rating | F30 [kN] | 1,8 | 2,6 | 7,0 | 10,0 | 16,0 | - | - | |

| F60 [kN] | 0,85 | 1,4 | 2,9 | 4,1 | 6,9 | - | - | ||

| F90 [kN] | 0,55 | 0,95 | 1,75 | 2,5 | 4,25 | - | - | ||

| F120 [kN] | 0,4 | 0,75 | 1,2 | 1,7 | 3,0 | - | - | ||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. Please refer to the European Technical Approval Guidelines (ETAG), Appendix C, for information on combining tensile and shear loads, the influence of the edge distance and groups of anchors. 2) The concrete has normal reinforcement. Higher values are possible for higher concrete compressive strengths. 3) For Würth W-HAZ-SK/S. | |||||||||

| Characteristic values | ||||||||

| Minimum spacing | smin ≥ [mm] | 50 | 50 | 60 | 70 | 100 | 100 | 125 |

| for c ≥ [mm] | 50 | 80 | 120 | 140 | 180 | 180 | 300 | |

| Spacing | scr, N [mm] | 150 | 180 | 213 | 240 | 300 | 345 | 375 |

| Minimum edge distance | cmin ≥ [mm] | 50 | 60 | 70 | 80 | 100 | 100 | 180 |

| for s ≥ [mm] | 100 | 120 | 175 | 200 | 220 | 220 | 540 | |

| Edge distance | ccr, N [mm] | 75 | 90 | 106,5 | 120 | 150 | 172,5 | 187,5 |

| Minimum member thickness | hmin [mm] | 100 | 120 | 140 | 160 | 200 | 230 | 250 |

| Effective anchorage depth | hef [mm] | 50 | 60 | 71 | 80 | 100 | 115 | 125 |

| Nominal drill diameter | d0 [mm] | 10 | 12 | 15 | 18 | 24 | 24 | 28 |

| Diameter of cutting edges | dcut ≤ [mm] | 10,45 | 12,5 | 15,5 | 18,5 | 24,55 | 24,55 | 28,55 |

| Drill hole depth | h1 ≥ [mm] | 65 | 80 | 95 | 105 | 130 | 145 | 160 |

| Through hole in the component being connected | df ≤ [mm] | 12 | 14 | 17 | 20 | 26 | 26 | 31 |

| Torque while installing anchor | Tinst = [Nm] | 15/103) | 30/253) | 50/553) | 80/703) | 160 | 160 | 280 |