Flat steel concrete anchor L-profile

Concrete flat steel anchor

CONCFLSTANC-40X40X300X2,0

Register now and access more than 125,000 products

- Versatile applications for simple tensile connections

- Easy height adjustment on uneven substrates

- Sheet metal hot-dip galvanised on both sides (S250GD + Z275 (approx. 20 µm)), thickness 4 mm in line with EN 10346:2009

- Application in utilisation classes 1 and 2 in line with EN 1995:2013

European Technical Approval ETA 14/0274

- Torsion-free load application is assumed.

- The holes should be nailed starting from the end of the flat steel concrete anchor.

- At least 4 nails should be used and the amount is based on the static calculation. The nails used must have a diameter that fits the holes in the flat steel concrete anchor.

- Live edges are not permitted; the entire surface of the flat steel concrete anchor must lie against the wood.

- The components must be thicker than the penetration depth of the nails.

- The respective basic conditions of the applicable anchor approval must be observed

- Steel failure under bending stress is decisive for flat steel concrete anchors that are fastened in concrete using 43 mm x 4 mm metal anchors and washers in accordance with EN ISO 7094.

- Steel failure under tensile stress is decisive for embedded flat steel concrete anchors.

| Notes: |

| Ring-shank nails 4x40 mm must be used for securing in accordance with EN 14592. No specified nail pattern needs to be observed with regard to the nailing method according to ETA 08/0259. Partial nailing is permitted. The specified load-bearing capacities are for softwood with a characteristic density of rk ≥ 350 kg/m³. Design value of the load-bearing capacity of a nail: FVM,Rd = kmod/gM × F1,Rk with gM = 1.3 Design value of the steel load-bearing capacity for anchor mounting in concrete: Fm,Rd = Fm,Rk/gM0 with gM0 = 1.0 Design value of the steel load-bearing capacity for tension anchors in concrete: Ft,Rd = Ft,Rk/gM2 with gM2 = 1.25 Design value of the total load-bearing capacity for anchor mounting: F1,Rd = min {n × FVM,Rd; Fm,Rd} with n = number of nails Design value of the total load-bearing capacity for tension anchors in concrete: F1,Rd = min {n × FVM,Rd; Ft,Rd} with n = number of nails The minimum distances for nails for sheet steel-wood connections in accordance with EN 1995-1-1 must be observed. |

European Technical Approval ETA 14/0274

Subject to technical changes!

Datasheets(X)

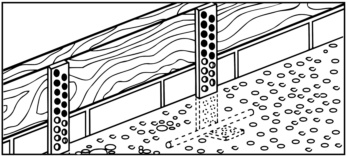

Embeddable, height-adjustable tension tie connection for connecting wall elements or posts in concrete base materials.

Suitable fasteners:

- Comb/ribbed nail in line with EN 14592: 4.0 x ≥ 30 mm.

- Recommended dowels for anchoring in concrete: W-BS; W-FAZ; W-VIZ; WIT-VM 250

| |

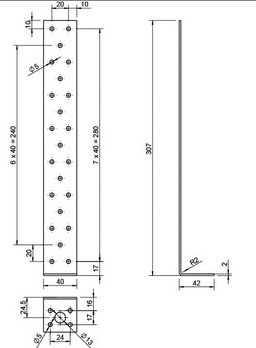

Width x height x depth | 40 x 307 x 42 mm |

Thickness | 2 mm |

Hole diameter in subcarrier nJ/main carrier nH 2 | 5 / 5 + 13 mm |

Number of D 5 mm holes in subcarrier nJ/number of D 5 mm + D 13 mm holes in main carrier nH | 23 / 4 + 1 PCS |

Distance between support and centre of hole | 24.5 mm |

Weight | 207 g |

Approval | ETA-14/0274 |

Steel failure, bending (FBRk,mB) | 3.33 kN |

Steel failure, tension (FBRk,tB) | 17.8 kN |

Material | Steel |

Material designation | S250GD |

Material standard | DIN EN 10346:2009 |

Surface | Hot dip galvanized |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!