Drilling screw, hexagon head with wood thread and sealing washer piasta®

Slf-dr scr, f/con, piasta, hx, sl wsh

SCR-DBITR-WOTHR-WSH16-(RUS)-6,0X50

Art.-no. 021480650

EAN 4046778775388

Register now and access more than 125,000 products

The sealing washer consists of an A2 stainless steel metal back with vulcanised seal made of high-quality EPDM

The screw with the sealing washer ∅ 14 mm, 3 mm EPDM is particularly suitable for fastening corrugated profiles (e.g. 18/76) on wooden substructures

Suitable for component combinations tI / tII according to approval ETA-10/0184

- Steel / wood

- Aluminium/wood

The material thickness to be drilled is max. 2 mm. However, it is possible to drill two sheets (2 x 1.5 mm) in one step.

Datasheets(X)

CAD data (available after login)

| |

Material | Stainless steel A2, 1.4301 |

Surface | Flake zinc |

Material of sealing washer | Stainless steel A2 |

Surface of the sealing washer | Plain |

Material of gasket | Ethylene propylene diene terpolymer rubber |

RoHS-compliant | Yes |

Head type | Hexagon head with collar |

Drive type | Hexagon |

Thread type | Wood screw thread |

Shape of tip | Drilling tip |

Underground | Wood |

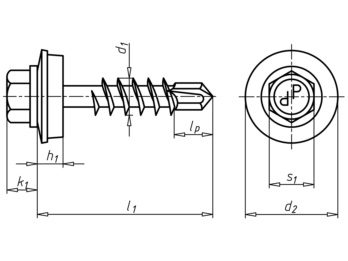

Nominal diameter (d1) | 6 mm |

Length (l1) | 50 mm |

Outside diameter of the sealing washer (d2) | 16 mm |

Washer thickness (h1) | 3 mm |

Head height (k1) | 5.4 mm |

Drill tip length (lp) | 5.7 mm |

Screw-thread length with drill tip | 41 mm |

External drive (s1) | WS8 |

Max. material thickness to be drilled through (metal) | 2 mm |

Min. recommended substructure thickness | 40 mm |

Approval | ETA-10/0184 |

Min./max. recommended installation speed (idling) | 1200-1800 rpm |