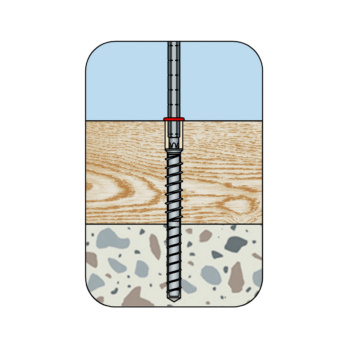

Concrete screw anchor W-SA TC, Timber Connect

Screw anchor, W-SA TC Timber Connect

ANC-(W-SA TC)-T30-(DPS)-40/150-7,5X100

Art.-no. 0901575100

EAN 4050382226556

Register now and access more than 125,000 products

- Quick and easy push-through installation using a tangential impact driver

- High transferable tensile and shear loads

- Loads do not depend on fixture thickness

- One screw size for all wood thicknesses

- Invisible sill fastening: The small screw head can be countersunk in the wooden beam

- Can be loaded immediately - no need to wait

- Almost no expansion effect, small edge distances possible

DIBt National technical approval: Z-21.1-1917: Anchoring of wooden components in concrete

Design

- Anchoring in concrete: Design in accordance with DIN 1992:-4-2019-04

- Anchoring in wood: Design in accordance with DIN EN 1995-1-1_2010-12 in conjunction with DIN EN 1995-1-1/NA:2013-08

taking into account the additions and instructions from Z-21.1-1917

According to approval Z-21.1-1917, the screw anchor must be processed with the appropriate setting tool and a suitable tangential impact driver.

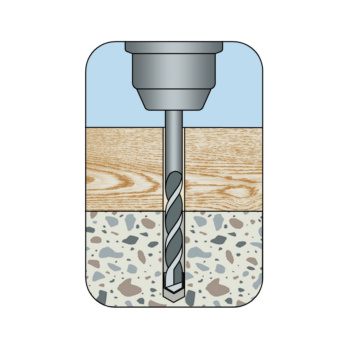

Create the drill hole

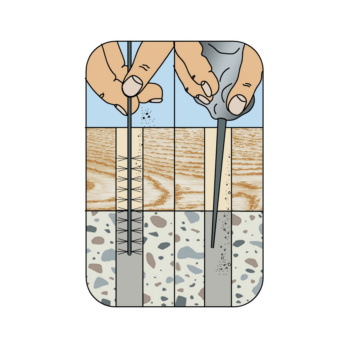

Clean the drill hole

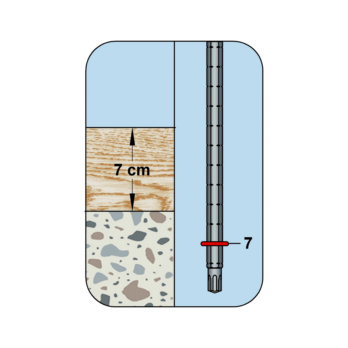

Adjust wood thickness [cm] on setting tool

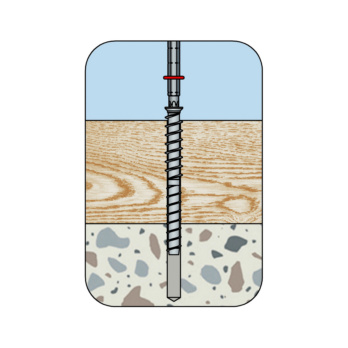

Set screw anchor with tangential impact screwdriver

The screw anchor is correctly set when the marking [setting tool] is flush with the surface

DIBt National technical approval: Z-21.1-1917: Anchoring of wooden components in concrete

Design

- Anchoring in concrete: Design in accordance with DIN 1992:-4-2019-04

- Anchoring in wood: Design in accordance with DIN EN 1995-1-1_2010-12 in conjunction with DIN EN 1995-1-1/NA:2013-08

taking into account the additions and instructions from Z-21.1-1917

Datasheets(X)

CAD data (available after login)

For anchoring wooden components in cracked and uncracked concrete:

For example, for fastening wooden components such as sills, inferior purlins, beams, substructures etc. to concrete

- In static and quasi-static loads in reinforced or non-reinforced normal weight concrete with a concrete compressive strength of at least C20/25 and at most C50/60 in accordance with EN 206-1:2001-07

- Use in dry indoor conditions only

The screw anchor can be used to connect the following types of wooden components:

- Solid wood made of softwood of at least grade S10 or strength class C24 in accordance with DIN EN 14081-1:2011-05 in conjunction with DIN 20000-5:2012-03

- Glued laminated timber in accordance with DIN EN 14080:2013-09

- Laminated beams of at least grade S10 or strength class C24 in accordance with DIN EN 1408:2013-09 or according to DIBt National technical approval

- Laminated veneer lumber in accordance with DIN EN 14374:2005-02

- Cross-laminated timber in accordance with DIBt National technical approval or European Technical Assessment

Anchor diameter | 7.5 mm |

Anchor length (l) | 100 mm |

Min./max. height of the fixture (t fix) | 40-150 mm |

Nominal drill-bit diameter (d 0) | 6.0 mm |

Drill hole depth (h 1) | 65 mm |

Embedding depth (h nom) | 55 mm |

Internal drive | TX30 |

| Performance data in accordance with Z-21.1-1917 of an individual anchor without influence of the edge distance in concrete | Nominal anchor diameter [mm] | 7,5 | 10 | 12 | ||||

| Basic conditions in accordance with DIN EN 1995-1-1 | Type of wood and wood strength: Softwood C24 Utilisation class 1 Load action: Medium (kmod = 0.8) | |||||||

| Admissible tension load1) | Nadm [kN] (cracked concrete C20/25, s≥3 hef, c≥ 1.5 hef) | Nadm [kN] | 1.322) | 2.662) | 4.212) | |||

| Fixture: Softwood C24 | d3) | 0° | 90° | 0° | 90° | 0° | 90° | |

| Adm. shear load 1) | Vadm [kN] (cracked concrete C20/25, s≥3 hef, c≥1.5 hef) | tfix [mm] = 40 | 1,23 | 1,07 | - | - | - | - |

| tfix [mm] = 60 | 1,23 | 1,07 | 1,96 | 1,70 | - | - | ||

| tfix [mm] = 80 | 1,23 | 1,07 | 1,96 | 1,70 | 2,95 | 2,54 | ||

| tfix [mm] = 100 | 1,23 | 1,07 | 1,96 | 1,70 | 2,95 | 2,54 | ||

| Fixture: Softwood C24 | tfix [mm] = 150 | 1,23 | 1,07 | 1,96 | 1,70 | 2,95 | 2,54 | |

| tfix [mm] = 200 | - | - | 1,96 | 1,70 | 2,95 | 2,54 | ||

| tfix [mm] = 250 | - | - | - | - | 2,95 | 2,54 | ||

| tfix [mm] = 300 | - | - | - | - | 2,95 | 2,54 | ||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. For information on combining tensile and shear loads, on the influence of the edge distance and on anchor groups, please refer to EN 1992-4. 2) The admissible value contains the failure type "head pull-through" by the wooden fixture "softwood C24" in accordance with DIN EN 1995-1-1. 3) d = angle between force and grain 0° means, for example, that the force acts in the direction of the grain (intermediate values can be interpolated). | ||||||||

| Installation parameters | Nominal anchor diameter | [mm] | 7,5 | 10 | 12 |

| Nominal drill diameter | d0 | [mm] | 6,0 | 8,0 | 10,0 |

| Diameter of cutting edges | dcut ≤ | [mm] | 6,4 | 8,45 | 10,45 |

| Drill hole depth (in concrete) | h1 ≥ | [mm] | 65 | 75 | 85 |

| Length of thread engagement in concrete | hnom | [mm] | 55 | 65 | 75 |

| Effective anchorage depth | hef | [mm] | 40 | 47,5 | 54,5 |

| Nominal drill diameter in wooden fixture | d0,w = | [mm] | 6,0 | 8,0 | 10,0 |

| Countersunk head diameter | dh= | [mm] | 10,0 | 16,0 | 17,0 |

| Minimum spacing | smin | [mm] | 40 | 50 | 60 |

| characteristic spacing | scr,N | [mm] | 120 | 142,5 | 163,5 |

| Minimum edge distance | cmin | [mm] | 40 | 50 | 60 |

| characteristic edge distance | ccr,N | [mm] | 60 | 72 | 82 |

| Minimum member thickness | hmin ≥ | [mm] | 100 | 115 | 125 |

| Drive | TX | 30 | 45 | 50 | |

| max. power output of the tangential impact driver as specified by the manufacturer | Timp.max | [Nm] | 100 | 250 | 250 |

| Associated setting tool | Art. | 0901 757 001 | 0901 510 002 | 0901 512 001 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!