ASSY ® 3.0 HCR chipboard screw

ASSY 3.0 HCR partial thread countersunk head AW

SCR-CS-WO-HCR-AW20-5X60/37

ASSY 3.0

Register now and access more than 125,000 products

Minimal splitting effect, especially when screwing in near the edge

Tip with ring thread

Short screw-in times

Asymmetrical coarse thread

Countersunk head with AW drive

Corrosion-resistant HCR stainless steel (material no. 1.4539)

Pre-drilling to the core diameter in solid hard woods

ASSY 3.0 chipboard screws are optimised for use in wooden materials. Use in plastic anchors may cause a reduction in the load-bearing capacity. Therefore, we recommend only using screws without optimised thread tips (drill tip, mating thread, ring thread, serrated edge, self-clearing groove, etc.) in plastic dowels, e.g. Würth ASSY D, prefix 0151 (countersunk head) and prefix 0153 (pan head).

When using these screws, the ETA-11/0190 specifications must be observed.

Available work documents:

Timber dimensioning software, load tables and detailed processing instructions can be found on the service page www.wuerth.de/assy.

ETA-11/0190

Datasheets(X)

CAD data (available after login)

ASSY HCR 3.0 are made of highly corrosion-resistant steel, material no. 1.4539 (corrosion resistance class IV, Appr. No. Z-30.3-6), and are suitable and approved for use in the following areas:

- For components in stables

- In woods with a high tannic acid content

- Particularly good resistance to very aggressive media such as phosphoric acid, sulphuric acid and hydrochloric acid media, high resistance to pitting and stress fracture corrosion

Screw-in angle 0° to 90°. For coniferous wood or wood-based materials made from softwood, the screw connection is made without pre-drilling. To reduce the edge distances, a pre-drilled hole can be made according to the core diameter. When screwing into hardwood, pre-drill according to ETA-11/0190.

| |

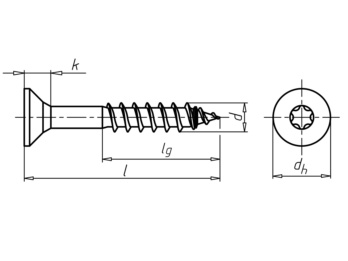

Nominal diameter (d) | 5 mm |

Length (l) | 60 mm |

Head type | Countersunk head |

Head diameter (dh) | 10 mm |

Head height (k) | 3 mm |

Internal drive | AW20 |

Thread type | Wood screw thread |

Thread design | Partial thread |

Thread form | Single start thread |

Thread length (lg) | 37 mm |

Core diameter | 3.2 mm |

Shape of tip | Tip with ring thread |

Angle of the tip | 30 Degree |

Material | Stainless steel, 1.4539, X1NiCrMoCu25-20-5 |

Surface | Plain |

Min./max. screw-in angle | 0-90 Degree |

Product weight (per item) | 5.000 g |

Suitable for use in the following materials | Board ply wood (BSP), Wood, Derived timber product, Hardwood, LVL, Softwood |

Area of application | Outdoors, Façades, Wet areas, Timber construction, Ocean climate, Casing, Play equipment, Board walk, Terrace, Fence |

Approval | ETA-11/0190 |

Screw requiring approval | Yes |

RoHS-compliant | Yes |

| The range of applications of the various stainless steels is detailed in the following table issued by the ISER (German Information Office for Rustproof Stainless Steel, Non-Rusting Steels for Various Environmental Conditions, www.edelstahl-rostfrei.de, Information Sheet 828). Rustproof stainless steels (e.g. material no. 1.4016) are recommended in terms of atmospheric conditions only for use in a rural environment, and in this respect only subject to significant restrictions. We therefore recommend only using austenitic stainless steels for outdoor applications, taking the environmental conditions into account. | ||||||||||||||

| Steel quality Short name | Material no. | Environment | ||||||||||||

| Country | City | Industry | Close to the sea | |||||||||||

| N | M | H | N | M | H | N | M | H | N | M | H | |||

| X1NiCrMoCuN25-20-7 | 1.4529 | Würth HCR (0180 904...) | + | + | + | + | + | + | + | + | + | + | + | + |

| X1NiCrMoCu25-20-5 | 1.4539 | Würth HCR (0180 940...) | x | x | x | x | x | x | x | x | + | x | x | + |

| X5CrNiMo17-12-2 | 1.4401/1.4578 | Würth A4 (0169 015...) | x | x | x | x | + | + | + | + | (+) | + | + | (+) |

| X5Cr-Ni18-10 | 1.4301/1.4567 | Würth A2 (0166, 0180, 0181) | + | + | + | + | + | (+) | (+) | (+) | - | + | (+) | - |

| X6Cr17 | 1.4006 | Many competitors | (+) | (+) | (+) | (+) | - | - | (+) | - | - | - | - | - |

| Non-rusting steels for various environmental conditions (www.edelstahl-rostfrei.de, Information Sheet 828) | ||||||||||||||

| N= lowest corrosion load within the respective environment, indicated e.g. by low temperatures and low humidity M= medium corrosion load within the respective environment H= highest corrosion load within the respective environment, e.g. due to continuous high humidity, high ambient temperatures, particularly aggressive air pollution x= meets the requirements in principle, however, cheaper steels may also be sufficient += probably best material choice in terms of corrosion resistance and costs (+)= adequate performance as long as certain precautionary steps are taken. Smooth surfaces and regular cleaning are required in particular -= heavy corrosion expected | ||||||||||||||